Our obsession with the “Genuine Orientation”

The company policy is to create products that are truly valuable to our customers and to continue to provide them with the highest degree of sincerity.

We do not

-spend time developing products with pretentious specifications (cannot use for mass-production),

-present technical data that is more dramatized and inflated than actually necessary,

In product development, we respond each customer’s particular requirements one by one in detail, study through to the limits of our ingenuity to maximize product performance, and try to propose the best solutions that exceed the requirements.

No matter how small the order quantity or how large the order volume, we ensure strict quality control.

We take pride in each and every product we supply.

Our significance of our existence is to continue to provide products that only we can make.

This is our ” resolution” and “pride” to continue to be ” Genuine Orientation”.

① Optimization technology for device testing

② Silvaco plating

③ High-current applicability

④ Technology to manufacture ultra-short pins with narrow pitch for mass production device testing

⑤ Approach to Kelvin testing

⑥ Quality policy

① Optimization technology for device testing

We consider the simultaneous design of pins and sockets, or in other words, “technical communication between pins and sockets,” to be of utmost importance.

We consider the pin, socket, and IC device as one unit.

We are convinced that pins and sockets should be developed under the same design philosophy in order to perform the most efficient testing on the target device.

Therefore, the most ideal case is when we can provide pins and sockets at the same time.

On the other hand, there are actually cases when a customer wants to change the manufacturer only for the pins because of poor test yield. “The pin is not good!”

Customer decides to switch to another vendor’s pin. This is a case where the pin is judged to be “usable as long as it can be physically seated in the socket”.

Since the pins and sockets are provided from different manufacturers, there is no technical communication in IC testing.

In some cases, this will work, and in others, it will not.

We analyze existing housings and custom design pins so that sockets can be used without modification, providing the most appropriate solution for any project under any conditions.

Our technology and know-how will prove to you that the integration of pin and socket design policies will result in better device test performance.

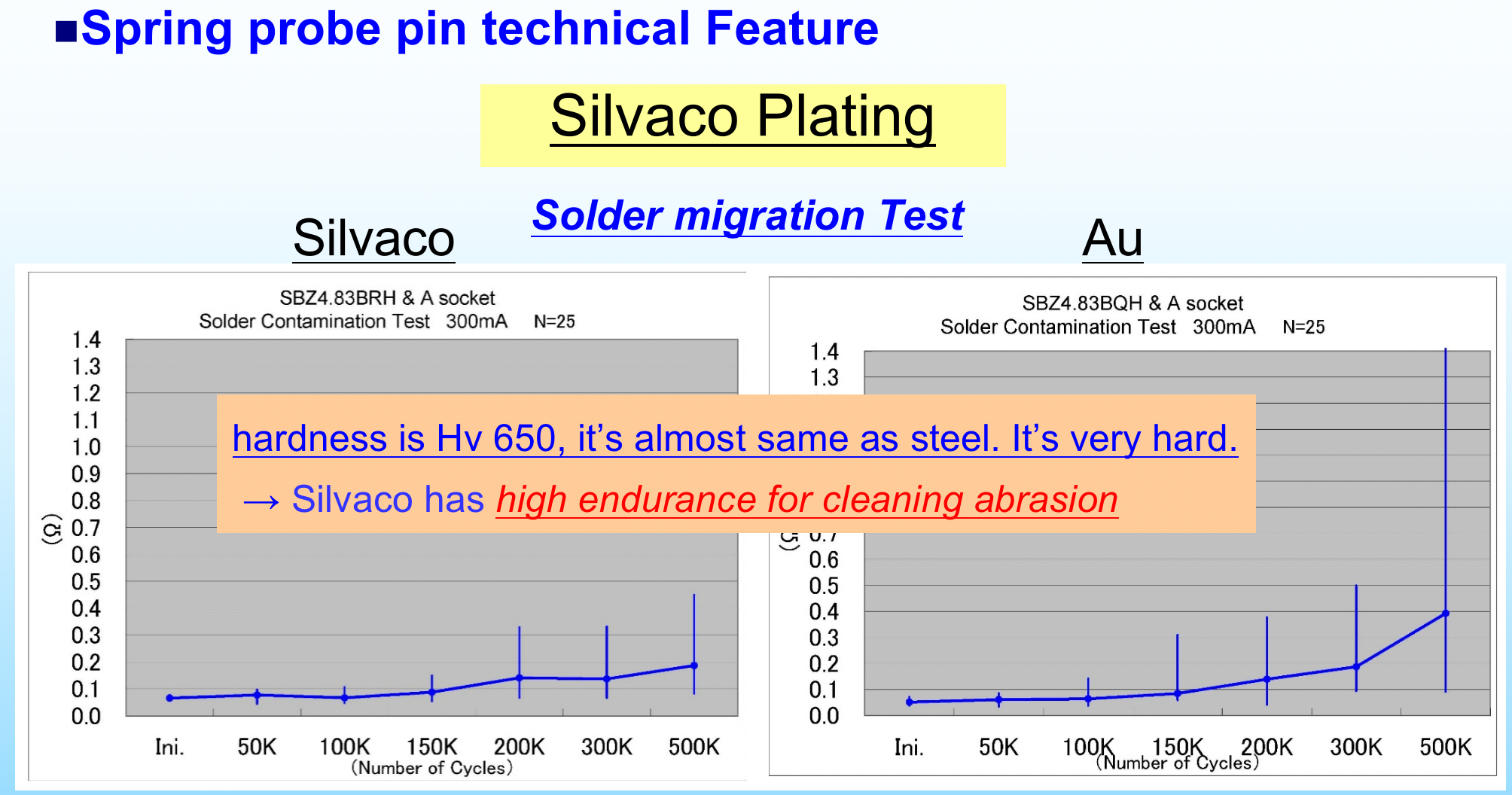

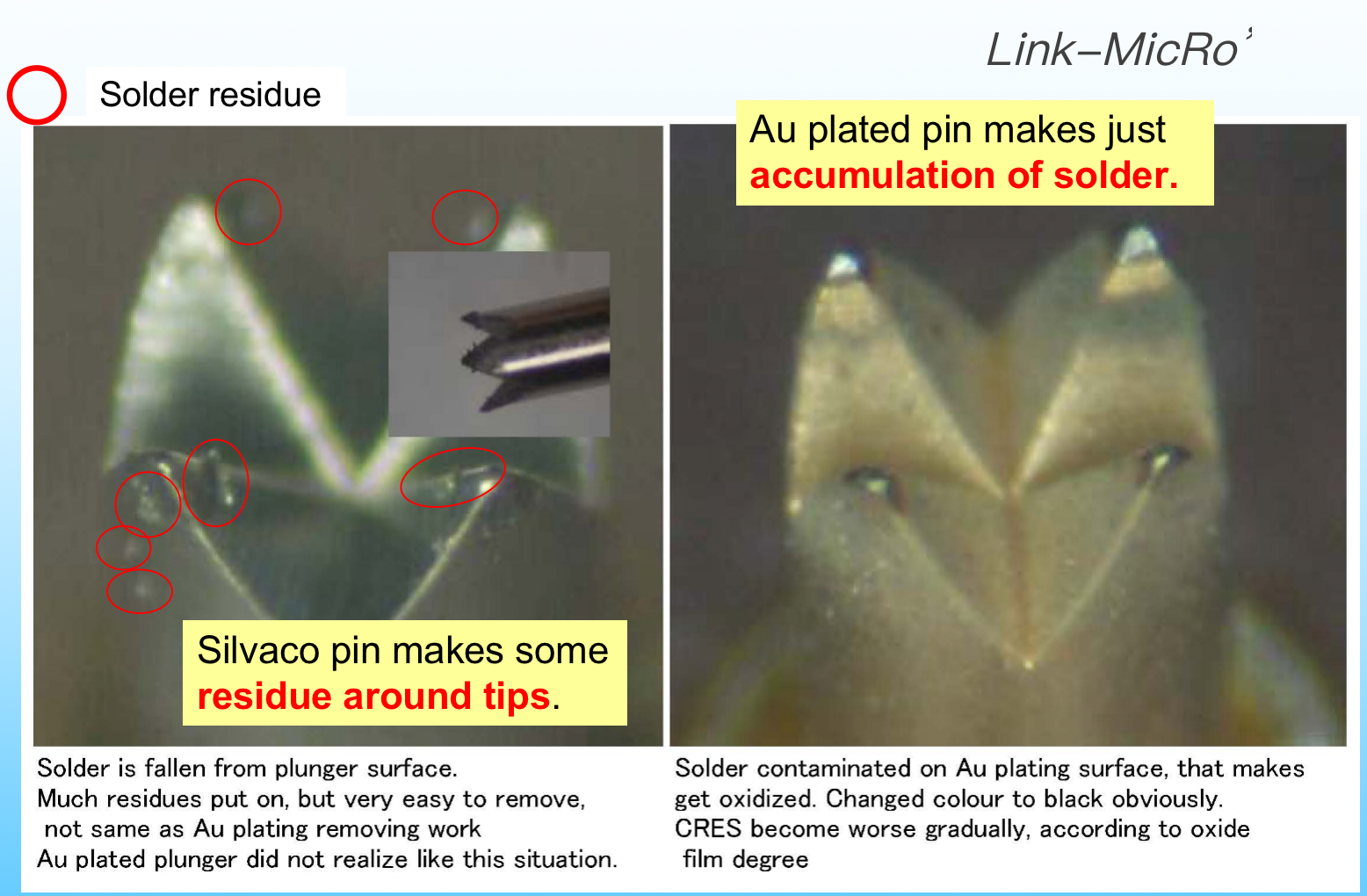

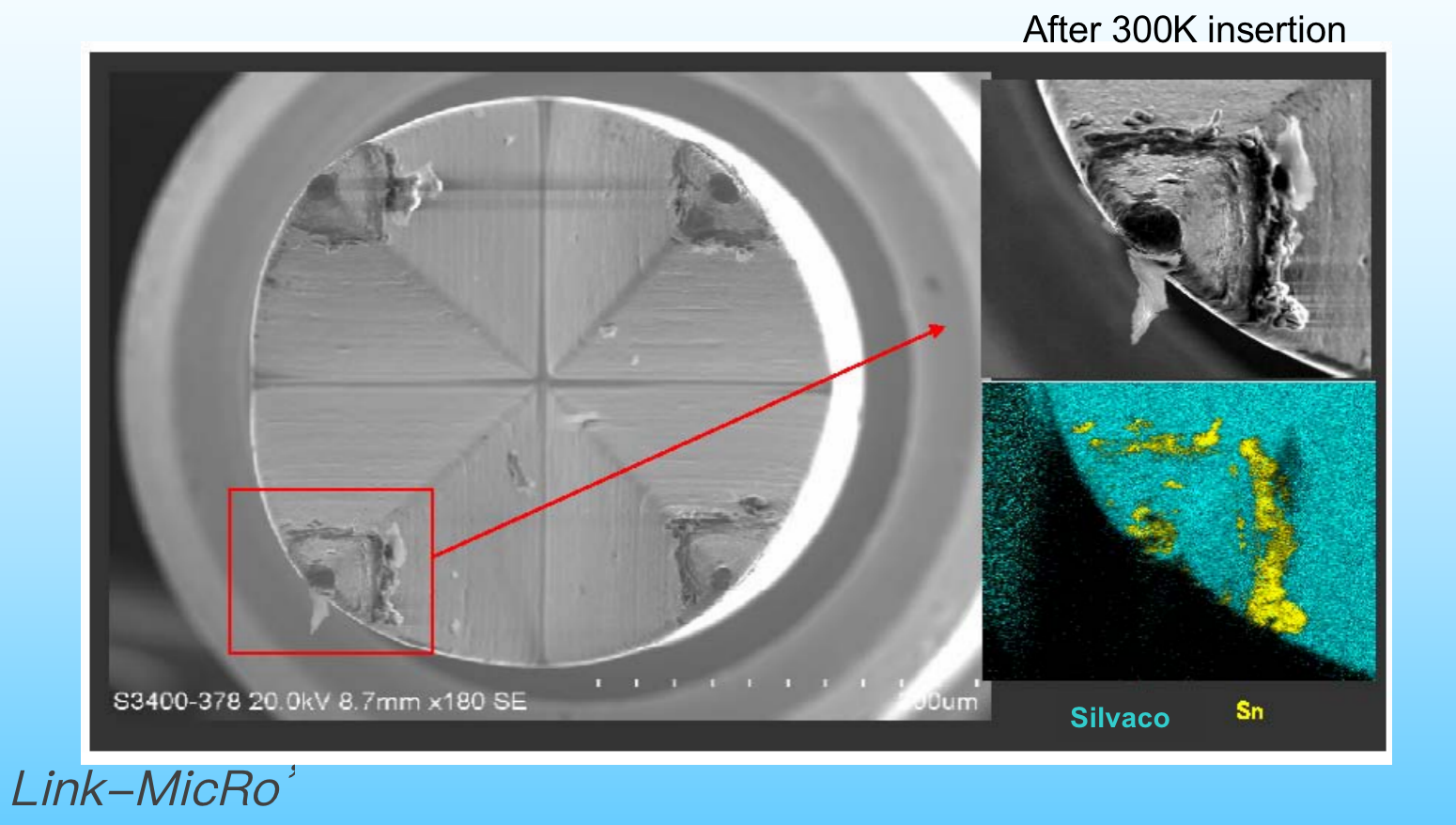

② Silvaco plating

Effective Solutions for Solder Migration by BGA Devices

Effectiveness of Silvaco Plating

(Developed for BGA devices especially ; also effective for QFN and QFP, but not as significant as in BGA device testing)

Optimizes solder-migration suppression specifications according to IC device type and testing environment based on technical know-how and experience.

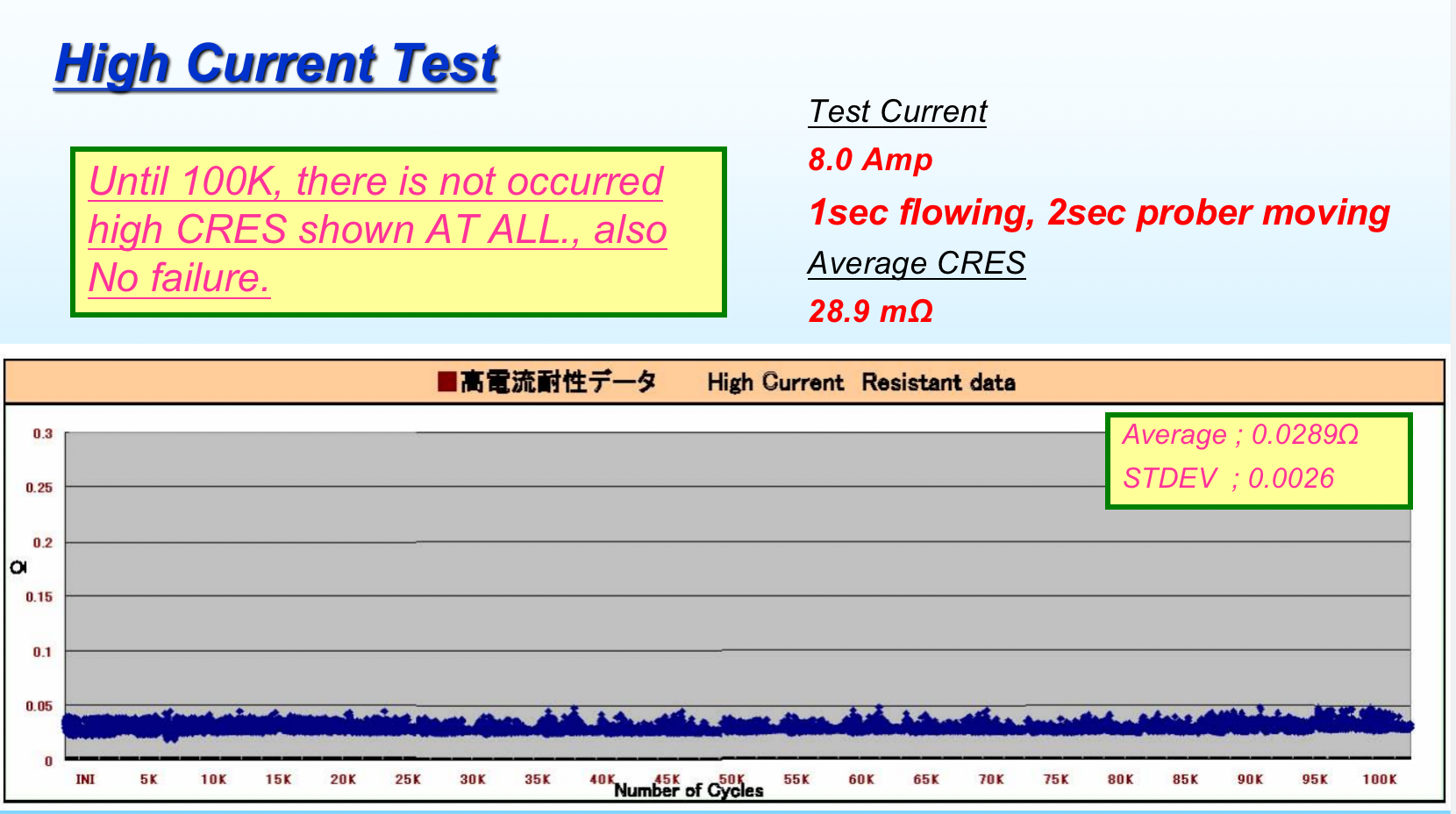

③ Applicable to large currents device test

life test data of 100,000 times shot by energizing for 1 second at 8A by DC basis.

Achieves energization of 10A at 0.65 pitch or higher, and/or 3A at 0.3 pitch

Much higher current is possible on the basis of current RMS value by pulse signal.

※RMS: Root Mean Square

We have our own original criteria for evaluating “high-current pins of good quality”.

The quality evaluation of high current pins should be based on the following factors,

Current flow (current value)

Duration of current flow

How many shots it can withstand

We believe that the quality evaluation of high-current pins should be evaluated in a composite assessment that combines the above factors.

So, what is the most important factor for a technology to withstand tens of thousands of high-current device contacts?

We affirm that it is the quality of the technology to recreate a consistently stable contact for every shot, as shown in the 100,000 shot data for 8A by our pins above.

Even if it repeats stable shots, if the pin resistance goes out of balance even once in thousands or tens of thousands of times, at that moment, the pin will burn out at the point of unstable contact. Our high current test experiments have proven this several times over.

Therefore, the particularly very high quality that which allows us to repeat the same contact performance consistently hundreds of thousands of times, must be required for high-current device testing.

We believe that continuous current-carrying specs with internal contacts secured cannot accurately judge, if the high-current performance and quality is high enough to be applicable for actual device testing.

The continuous current specification values listed in pin product catalogs do not tell us the pin contact stability of each shot every time.

Our technological strength is our ability to realize the repeatability of stable contacts, and by incorporating those technologies and know-how into the pin specifications requested by our customers, we are able to support high-current device testing.

It is equally important that the pins in the same lot delivered must be of the same quality with no variation in performance.

We are the only company that can do this through our own unique and complex quality assurance efforts.

We can provide our customers with reliable products and confidential solutions.

④ Manufacturing technology for short pins with narrow pitch for mass production device testing – 20GHz

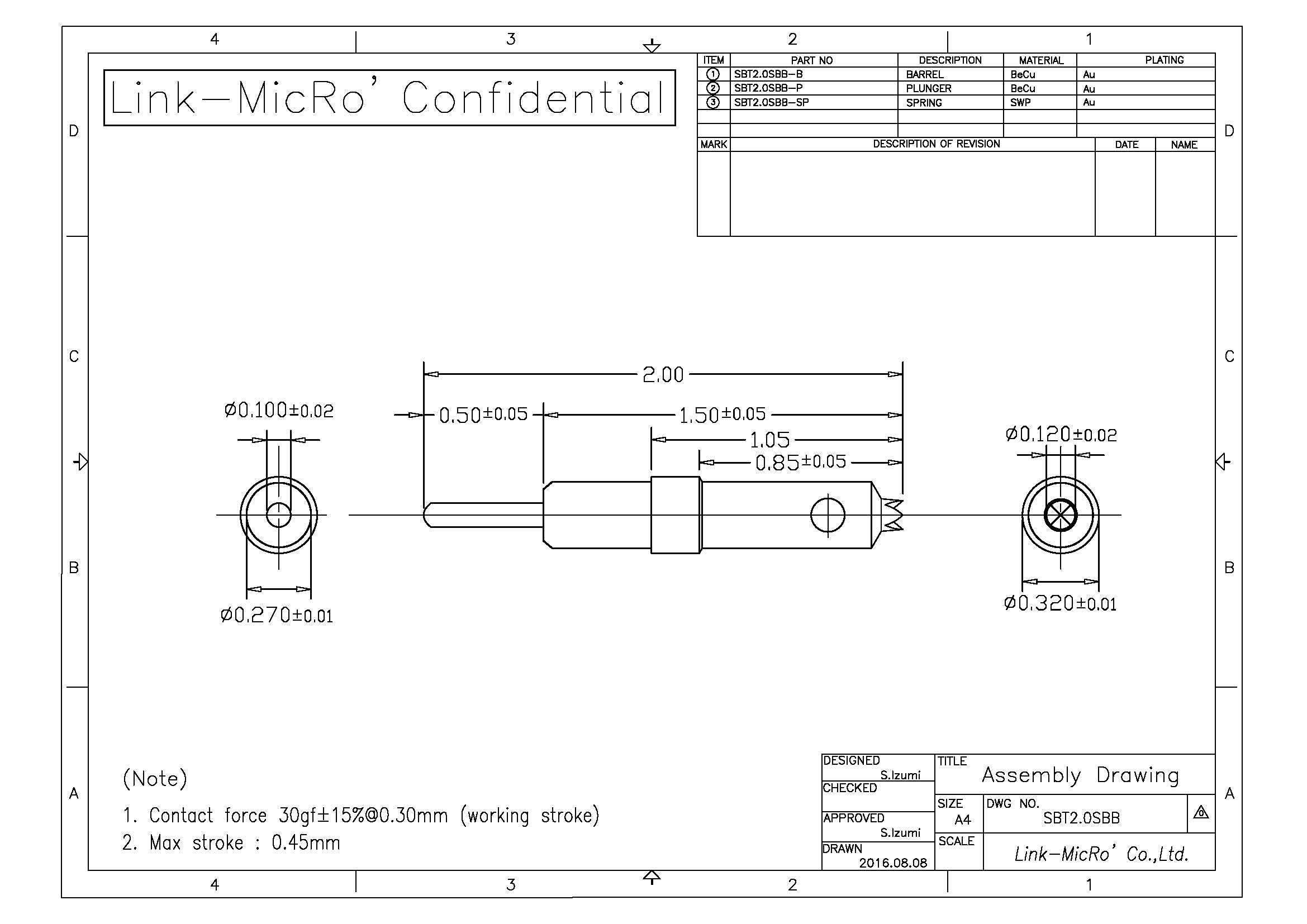

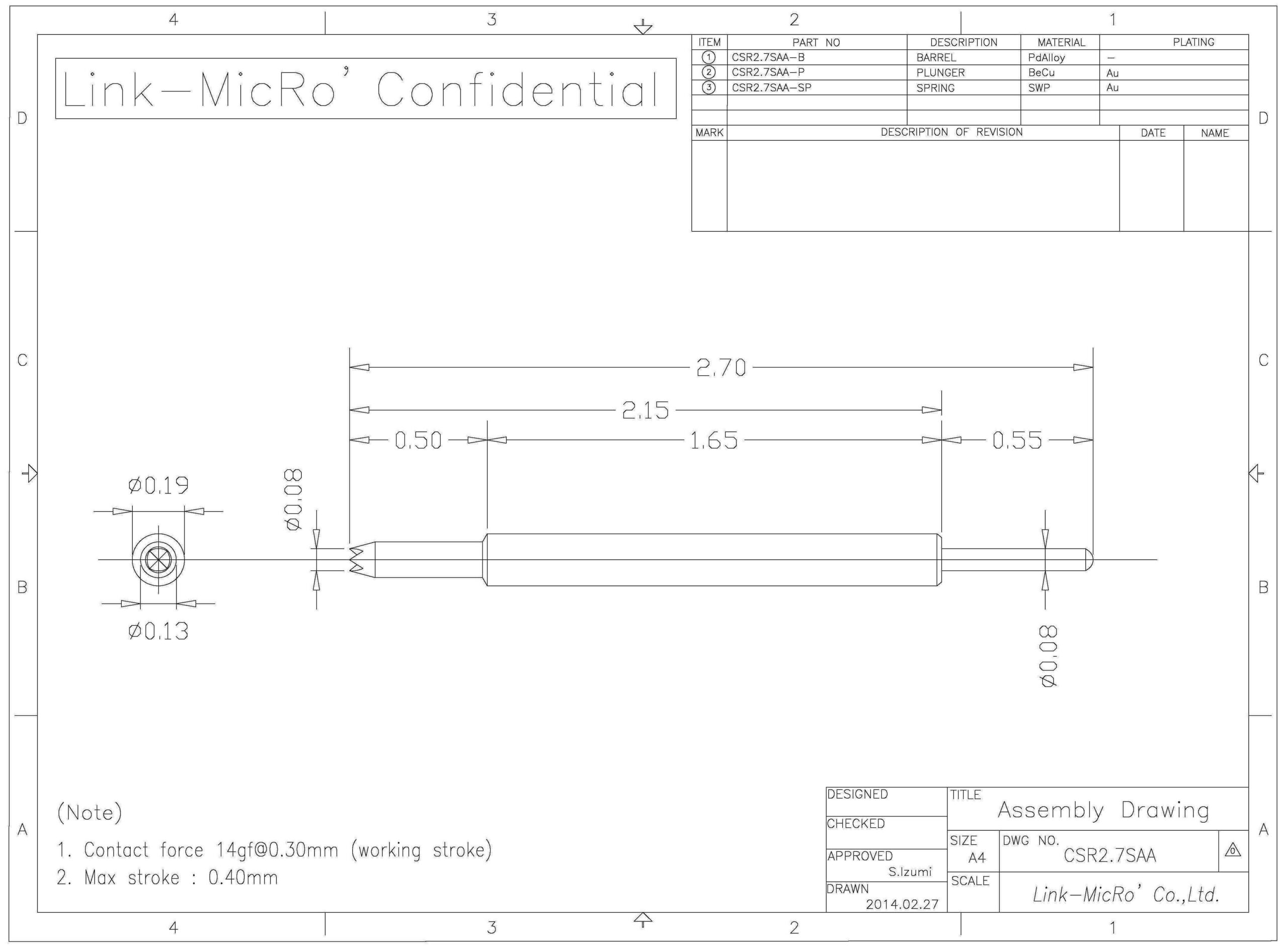

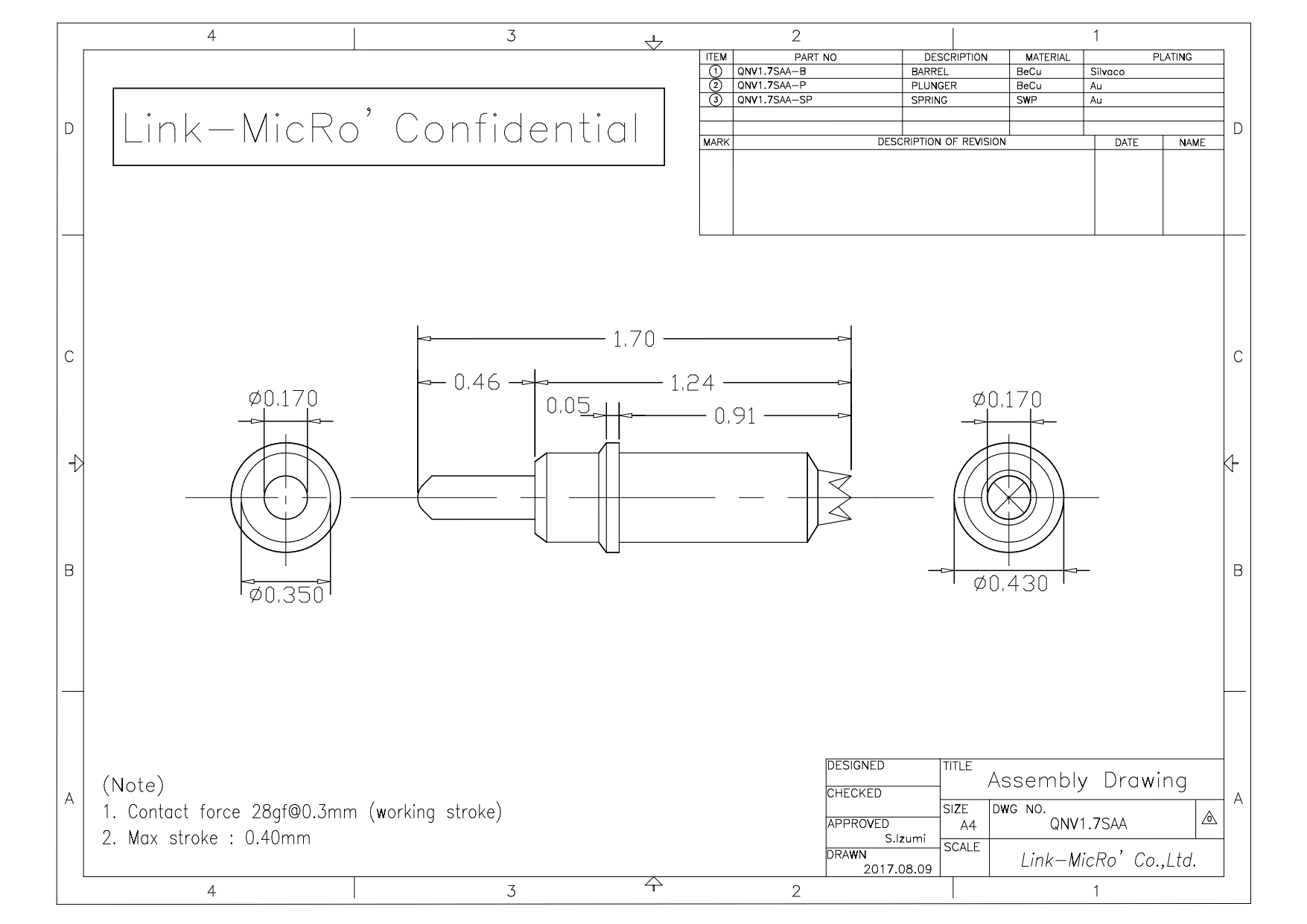

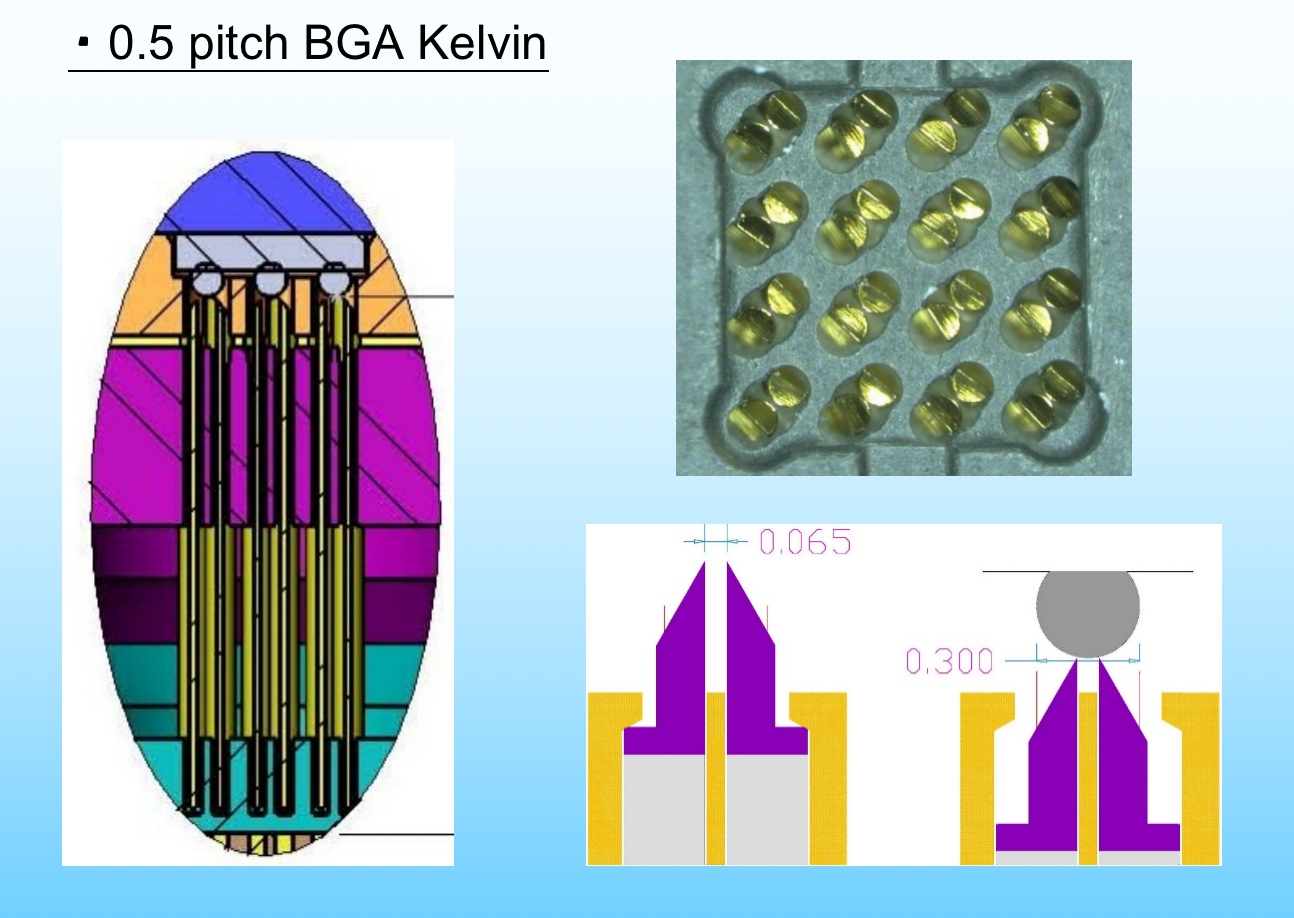

⑤ Approach to Kelvin Testing

We provide the best Kelvin solution from our know-how according to the IC package type and specifications.

Example of actual results ; Spring force of 30gf with barrel diameter of 0.22. High spring force solves the problem of pin tip slippage at the time of BGA contact.

⑥ Quality Target & Policy

Quality target

All pin must show same performance & quality until the end of pin life, even if any quantity pins in a lot.

Quality policy

1.We define to prioritize first to the all, design quality, manufacturing quality, QA/QC work quality, Quality of subcontractors management, and quality in all processes from order receipt to shipment.

2.In the product manufacturing process and inspection process, even if there is a pressure to shorten the delivery period due to a request from Sales Dept. etc., the work quality must not be degraded by it.

The manufacturing department and the inspection department must strive to maintain product quality as an independent department that prioritizes quality first in the company.